what is a dry type transformer ?

introduction

transformers are crucial components in the electrical power system used to step up or step down voltage levels between circuits circuits they ensure that electricity is transmitted efficiently and safely across long distance dry type transformers are unique of transformer that uses air instead of liquid for cooling with increasing demand for safer and greener power solution these transformers are becoming a preferred choice in many setting due to their fire resistance low maintenance needs and environmental benefits

what is a dry type transformer ?

a dry type transformer is an electrical device that uses air as a cooling medium instead of insulating oil it is typically enclosed in a protective casing dust and moisture intrusion

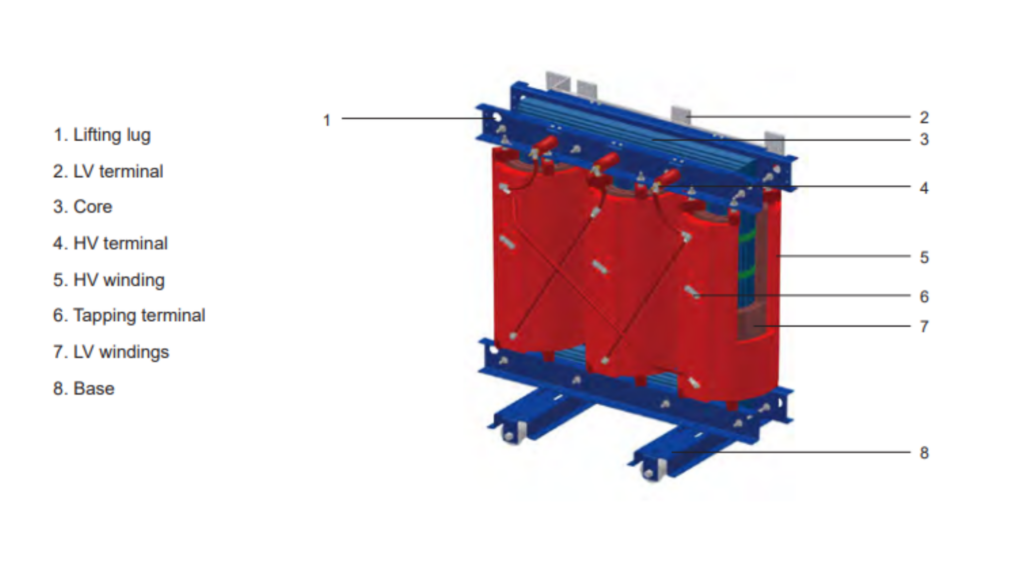

key components

core usually made of laminated steel

winding copper or aluminum

insulation system

ventilation system for cooling

differences from oil filled transformer used air instead of oil for cooling

safer for indoor use

more environmentally friendly

requires less maintenance

types of dry transformers

1. VPI ( Vacuum pressure impregnated ) transformers these use vacuum and pressure process t impregnate windings with resin they offer a strong mechanical strength and are moisture resistance

2. cast resin transformer : a windings are compactly in epoxy resin , providing high resistance to dust , moisture and chemicals ideal for environments

3. open wound transformer

have exposed winding and rely on air circulation for cooling they are more cost effective but less protected from the environment

How dry type transformer work

dry type transformer operate on electromagnetic induction when current flows through the primary winding it creates a magnetic field which induced voltages in the secondary winding

cooling process ;

use natural or forced air ventilation

heat generated is dissipated through air gaps and events

insulation and spacing play a key of in heat management

Advantages of Dry types transformer

fire safety : no flammable oils , ideal for indoor use

low maintenance : no need of oil cheeks or leak monitoring

eco- friendly : no risk of oil spills or contamination

flexible installation : can be installed indoor or out doors with proper enclosures

Dis- advantages of and limitations

lower power capacity : typically used medium to low voltages applications

cooling limitation : may require additional ventilation in hot or dusty areas

higher initial cost more expensive officers malls and residential complexes

Applications of dry type transformer

commercial building , officers and malls

industrial facilities : factories and manufacturing plants

renewable energy system : solar and wind energy station

hospitals and schools : where safety and noise control are critical

installation maintenance

site selection

choose well ventilated areas

ensure the site is dry and dust – free

proper grounding and surge protection

use of enclosures for added safety

routine maintenance: for dust or damage

regular cleaning of air events and filters

check insulation and terminal connections

Future trends and innovation :

smart transformer integration with IOT and automation

energy efficiency improvements : advanced material and designs

green energy demand : more dry type transformers in solar and wind application

compact designs for space constrained urban installations

conclusion

dry type transformer are becoming increasingly for popular for their safety , reliability and eco – friendly design whether in a hospitals a factory a solar power station they offer a safe and efficient power solution.

FAQS

1. what is the lifespan of dry type transformer?

typically 20 -30 years depending on the environment and proper ventilation

2. can dry type transformers be used outdoors ?

yes with weatherproof , enclosures and proper ventilation

3. are dry type transformer more expensive than oil filled ones ?

yes the initial cost is higher but maintenance costs are lower over time

4. what are safety standard for dry type transformers ?

they follows IES 60076-11 and ANSI /IEEE C57.12.91 standard for performance and safety