Oil Transformer the Complete guide

introduction

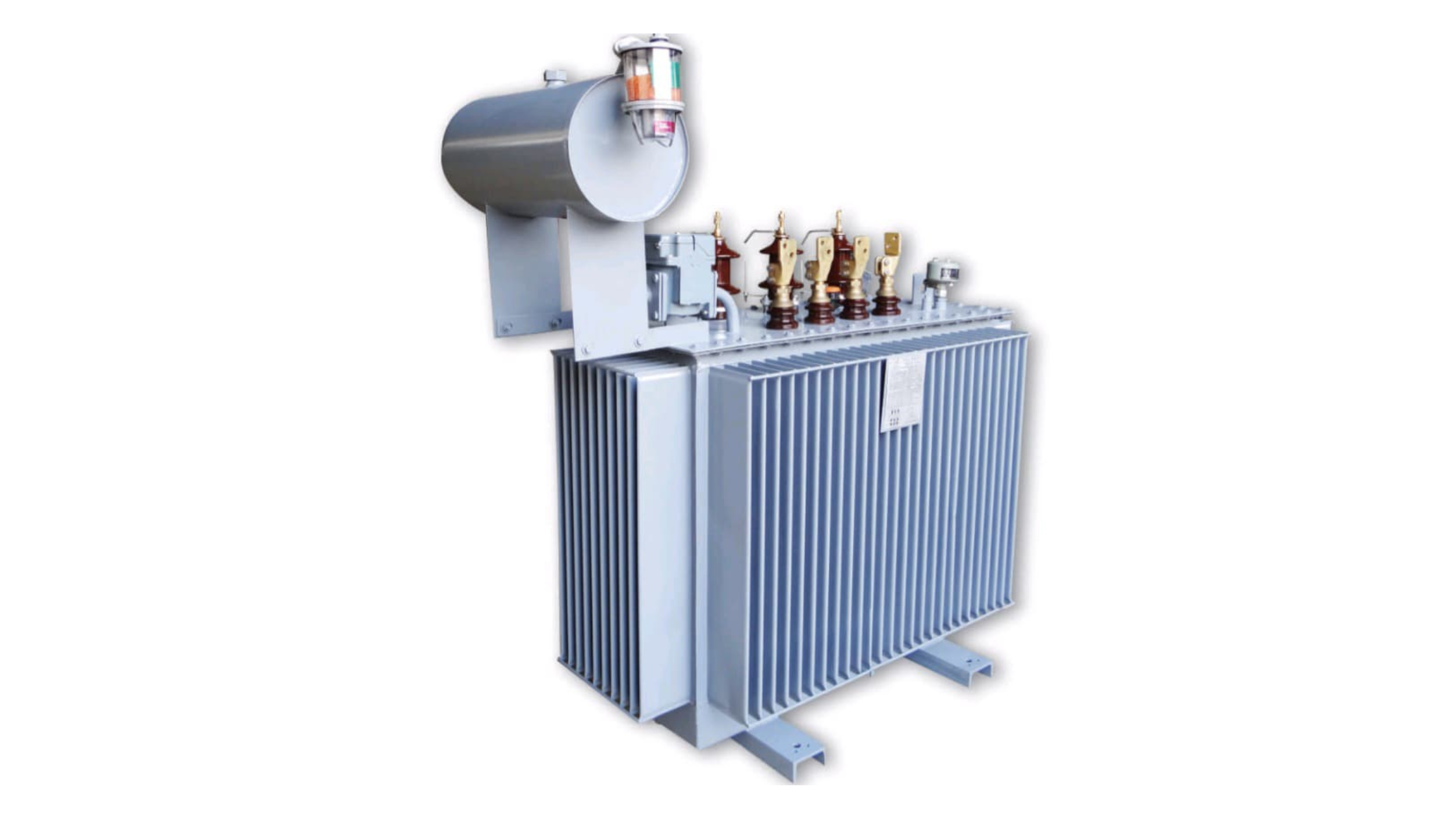

oil transformer in the world of electrical power system oil transforms plays a crucial role in the reliable of transmission and distribution of electricity these robust and high performance machines are designed to handle high voltage levels while ensuring maximum safety and efficiency by using insulating oil both a cooling and dielectric medium oil filled transformer can operate under demand conditions making them the preferred choice for utility industrial plant and power generation facilities

exploring transformer technology understanding hw oil transformer work their types , benefits and maintenance requirement is essential in this article we explore every thing you need to know about oil transformer from their principle and contraction to their real world applications.

what is an oil transformer

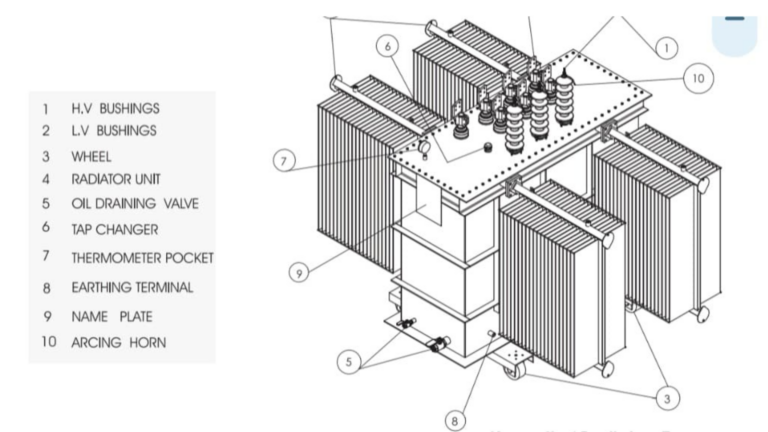

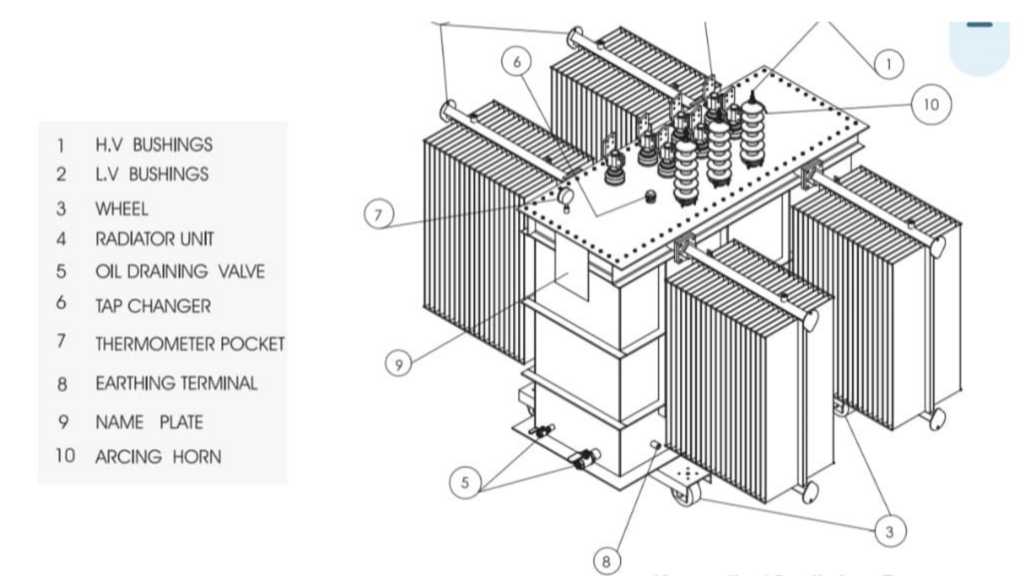

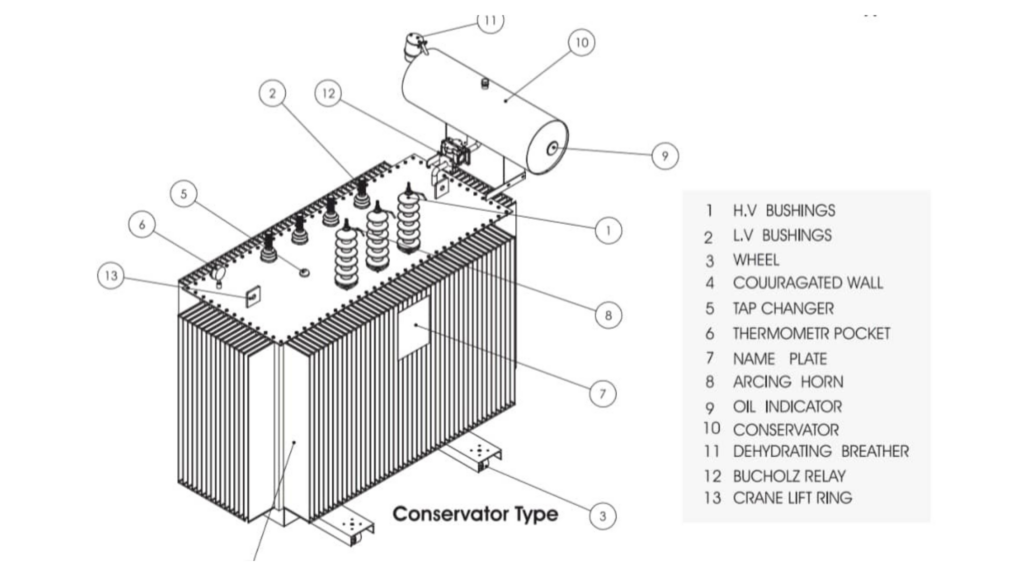

an oil transformer also know as an oil filled transformer is type of power transformer that uses insulating oils as a cooling and insulating medium this oil circulating with in transformer tank to absorb the heat generated by the winding and core dissipating it through radiator or cooling fins oi transformer are widely used in power distribution system , substation and industrial applications due to their efficiency and reliable in handling high voltage levels

how does oil transformer work ?

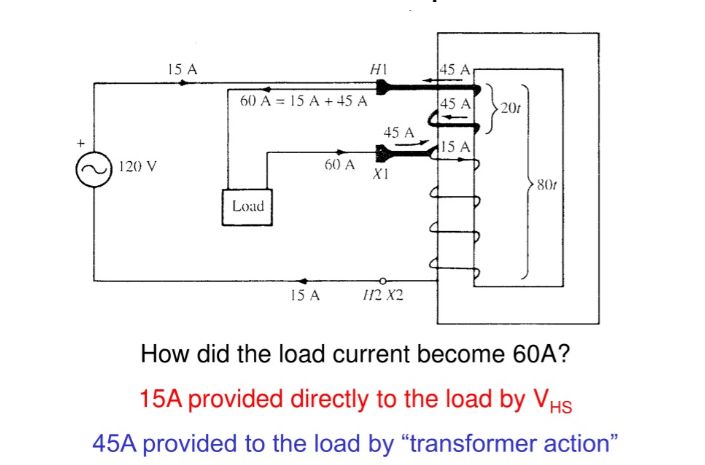

oil transformers operate on the principle of electromagnetic induction where electrical energy is transferred between winding through a magnetic field when voltage is applied to the primary winding it creates a magnetic flux in the transformers core which then induced voltage in the secondary winding as current flows through the winding heat is generated due to electrical resistance this heat is absorbed by the insulating oil , which circulating with in tank to cl the internal components and prevent overheating , adaxially the provides high dielectric strength enhancing insulation between internal parts and also helping t suppress arcing and electrical discharges.

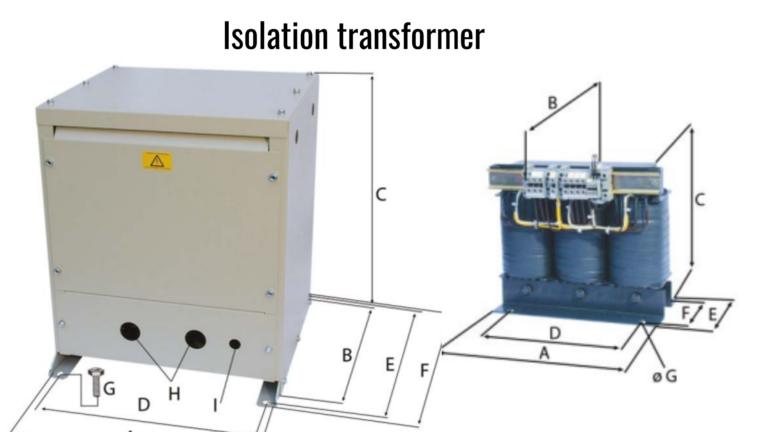

types of oil filled transformers

oil filled transformers come in various types are designed to meet specific operational requirements and environmental conditions the most common types include distribution transformers used for lower voltages application in residential and commercial areas and power transformers which handle higher voltages levels in transmission network based on commission there are hermetically sealed transformer which prevent air and moisture ingress and free breathing transformers which allow for air exchange through a breather system

additionally oil filled transformer are classified by cooling method such as

1. ONAN ( oil natural air natural )

2. ONAF ( oil natural air forced )

3. OFAF ( oil forced air forced )

which indicate how oil and air circulation are managed to dissipate heat efficiency

advantages of oil transformer

oil filled transformer offers several benefits

1. higher cooling efficiency

2. better overload capacity

3. longer lifespan with proper maintenance

4. superior isolation properties

5. cost effective for medium to high voltage applications

Dis advantages and challenges

1. fire hazard due to flammable oil

2. potential more regular maintenance

3. potential environmental contamination from oil leaks

large and heavier compared to dry transformers

key applications of oil transformers

1. utility substation and transmission network

2. industrial manufacturing facilities

3. renewable energy plant ( solar and wind farms)

4. railway and transportation systems

5. mining and oil gas installations

oil transformer maintenance and testing

outine maintenance is a essential for safe and reliable operation

key maintenance tasks

breather maintenance

radiator cleaning

gasket and bushing inspection

testing procedures

dissolved gas and analysis

dielectric strength testing

moisture content analysis

conclusion

oil transformer remains the backbone of modern power system their ability to handle high voltages with efficiency and reliability and long life makes them indispensable with evolving eco friendly oil and improved safety oil transformer continue to power industrial and utility infrastructure around the world

FAQS

1. why is oil used in transformer ?

transformer acts as both a coolant and insulating medium enhancing efficiency and preventing electrical break down

2. how often should transformer oil be changed ?

typically every 3 -5 years depending operating condition and result of oil testing

3. can oil transformer be used indoors ?

ts not recommended due to fire risks but dry type transformer are prevented for indoor use

4. what is the life span of an oil transformer ?

which proper maintenance oil transformer can last 20 -40 years or more