ABB Transformers | Types, Advantages,

Table of Contents

ABB history

ABB has over a century of experience with transformer technology. ABB was established in 1988 when Sweden’s ASEA (1883) merged with Switzerland’s BBC (Brown, Boveri & Cie, 1891): both transformed the electrical engineering fields they served. Prior to the merger, both companies were making strides with power transformers in support of high-voltage electrification in Europe. The merger added deep knowledge of power systems which laid the groundwork for ABB to lead the transformer manufacturing space on a global level.

Since then, ABB transformer technology has progressed and has global operations in more than 80 countries. ABB Power Grids was acquired by Hitachi Energy in 2020, including the transformer business, extending the ABB commitment to innovation; sustainability; and digital transformation. Today, ABB transformers are rely upon around the world for reliability, efficiency, and intelligent design, with applications for homes, industries, and infrastructure across the world.

ABB Power Transformers

- Power Transformers

What are they?

Power transformers play an essential role in transferring electric power from generating plants to the various parts of transmission and distribution systems. They operate at high voltage and high power (typically 10 MVA and higher).

ABB Power Transformer Solutions

ABB has a variety of different types of power transformers. ABB power transformers include:

Core-Type Transformers

Shell-Type Transformers

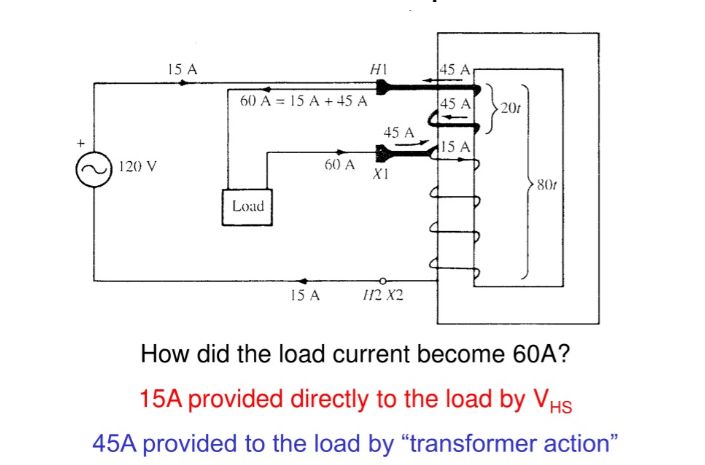

Auto Transformers

Generator Step-Up (GSU) Transformers

HVDC Converter Transformers

These transformers are built to meet international standards like IEC, ANSI, and IEEE. ABB’s TrafoStar core-form design is recognized worldwide for quality, compactness, and energy efficiency.

Use Case: Power transformers are used in all power plants, in high-voltage transmission substations, and heavy industrial applications. [ ABB Power Transformers]

Distribution Transformers

Domestic and commercial properties, as well as industrial plants, all require plug-in voltages from a higher voltage electrical power found in the transmission lines. Distribution transformers reduce high voltage electricity from the transmission lines, breaking bulk power down into usable voltages in a way similar to a bottle of soda, which lacks single servings until opened.

When using ABB Distribution Transformers, the following is offered:

- Based on raw material availability and their internal design considerations ABB distribution transformer primary voltages may be as high as 36 kV and could also have as high of a power rating as 25 MVA.

- As with ABB’s other transformer products they have Oil-Immersed and Dry-Type available in several configurations therefore supplying both indoor and outdoor utilization options.

- Each distributed transformer is customizable to the specifications of a rural grid, urban grid, industrial park, or commercial building.

- ABB Liquid Filled Transformer are widely used because they are known for their performance and resiliency in extreme environmental conditions, while Dry Type transformer are known for their safety when utilized indoors.

ABB Distribution Transformers

- Dry-Type and Liquid-Filled Transformers

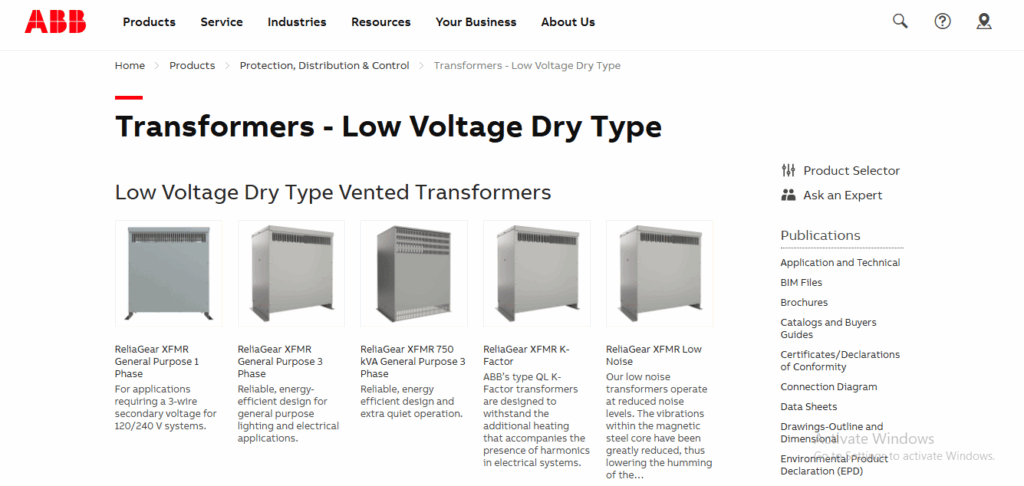

Dry-Type Transformer

- Does not use oil, air is used for cooling

- Low risk of burning down, maintenance is minimal

- Ideal for hospitals, commercial buildings, and tunnels

- Adverse windings are either Cast Resin or Vacuum Pressure impregnated (VPI)

Liquid-Filled Transformer

- Oil is used for ticking and insulation

- Rated for outdoor service

- Perform better under heavy load.

ABB provides both types, in order to have the design flexibility to remediate against environmental, safe and space conditions.

Control, Safety & Isolation Transformers

Control Transformers

TM-C control transformers from ABB provide consistent and reliable voltage to control circuits in industrial equipment. They play an essential role in automation panels because of their isolated windings and rugged construction.

Safety Transformers (TM-S)

These provide outputs for Safety Extra-Low Voltage (SELV) or Protective Extra-Low Voltage (PELV) that reduce electrical shock hazards, which they mostly used in schools, hospitals, and consumer electronics.

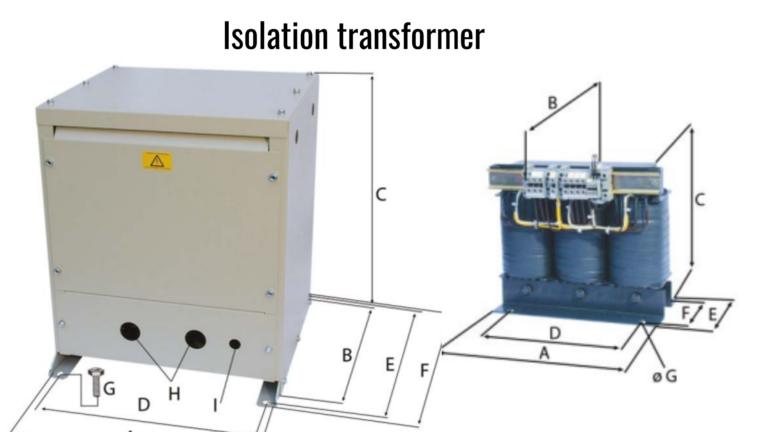

Isolation Transformers (TM-I)

isolation transformers offer galvanic isolation between input and output circuits. They are great for sensitive medical equipment, measuring instruments, and noise applications.

Read more on ABB Low Voltage Transformers

Instrument Transformers

Instrument transformers are used to reduce high current/voltage to practical levels for use by meters and other protective devices. ABB Provides: Current Transformers (CT) Voltage Transformers (VT) Combined Instrument Transformers They are very important for metering and protection in substations and Smart Grids.

ABB’s Digital and Sustainable Innovations

TXpert™ Ecosystem

ABB provides digital monitoring through an IoT-device that can track the health of a transformer in real-time using IoT devices, a few of the key features:

Predictive maintenance

Fault detection

Load monitoring

Lower maintenance costs and extension of lifespan

Eco-Design Transformers

ABB recognizes its obligation to reduce its carbon footprint with its:

Biodegradable ester fluids

Recyclable components

Energy-efficient designs

These transformers are eco-compliant (as per EU Eco Design) and ISO 14001 compliant.

Safe and Smart ABB Transformers

Benefits of Choosing ABB Transformers

All Around the World Compliance: IEC, ANSI, IEEE, et.al

Reliability: long life expectancy, low maintenance costs, rugged design plus more

Safety: flame-retardant dry-type models, high-voltage protection

Customizable: tailored for voltage, power, insulation, etc.

Energy Efficiency: advanced magnetic core materials, digital control reduces energy loss

Digital Intelligence: remote monitoring, predictive analytics, real-time diagnostics

ABB Transformer Applications

ABB transformers can provide power into many areas:

Industrial Plants – process automation, machinery, manufacturing

Commercial Buildings – proven, safe supply of electricity inside buildings

Residential Networks – local electricity supply to homes

Railway & Infrastructure – traction supply to railway stations

Substations and Utilities – voltage regulation and load balancing

Offshore Platforms – compact, durable, weatherproof transformers for maximum resistance and highly controlled environments

Renewable Power – dynamic, integrated solutions with wind, solar and hydroelectric systems

Conclusion

ABB has a transformer portfolio that covers application from high power transmission systems to compact indoor applications. ABB’s focus on innovation, sustainability while maintaining quality will continue to gain the trust of industries and governments across the globe.

If you are seeking safe, scalable, and future ready transformer solutions, ABB provides performance driven transformer solutions backed with over 100 years of proven engineering.

FAQ’S

- What is the lifetime of an ABB transformer?

ABB transformers are designed for a lifetime of 25 to 40 years, if they are properly maintained and operated under reasonable conditions.

2. Are ABB transformers customizable?

Yes, ABB can provide full customization based on voltage ratings, cooling methods, sizes, and special environmental requirements.

3. Are ABB dry-type transformers safe for indoor locations?

Yes. They are completely flame-retardant and produce no hazardous gas. Because of this, dry-type transformers are ideal for hospitals, schools, and commercial units.

4. Do ABB transformers come with digital monitoring?

Yes, ABB provides the TXpert™ digital ecosystem enabling smart diagnostics, remote monitoring and lifecycle management.

5. Where are ABB transformers manufactured?

ABB transformers are manufactured in factories located in various parts of the world including the USA, Europe, and Asia.