Single Phase Transformer | Complete Guide

Table of Contents

Introduction

Single-phase transformers are basic forms of electrical equipment in an electrical system which transfer alternating current from one circuit to another using electromagnetic induction. Transformers are an important part of electric power systems and can also be used for stepping voltage up or down, and isolating circuits. These transformers play a major role in the economic and efficient distribution of energy for residential, commercial and light industrial purposes. Understanding the operation and characteristics of these transformers will aid professionals in selecting and maintaining the right equipment for their specific requirements resulting in safer, more reliable, efficient, and economical systems.

This guide will explore single-phase transformers including the construction, operation, types, key parameters, advantages, and applications, installation practice, and frequently asked questions lets start .

What Is a Single Phase Transformer?

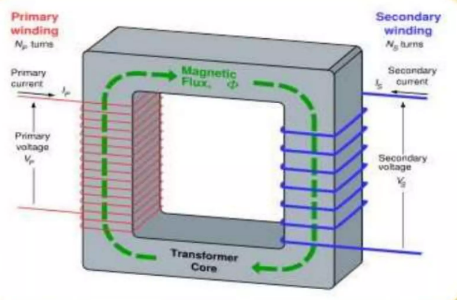

A single phase transformer is a passive electrical device that works on a single-phase AC supply and allows the transfer of electrical power from a circuit to another circuit. There are two windings on a single phase transformer, the primary and the secondary windings, which are magnetically coupled together by the laminated silicon steel core. With an alternating current flowing through the primary winding of the transformer, the alternating current will generate a time-varying magnetic flux which is magnetically linked to the scaled secondary winding. Based on Faraday’s Law

The main function of a single phase transformer is to either step up voltage (for transmission) or step down voltage (for utilization), without any changes to frequency. They allow for simple and reliable distribution of electrical power with a high efficiency factor; therefore, they offer excellent value for utility power distribution to urban and rural systems, especially if a three-phase transformer is not necessary or is too expensive .

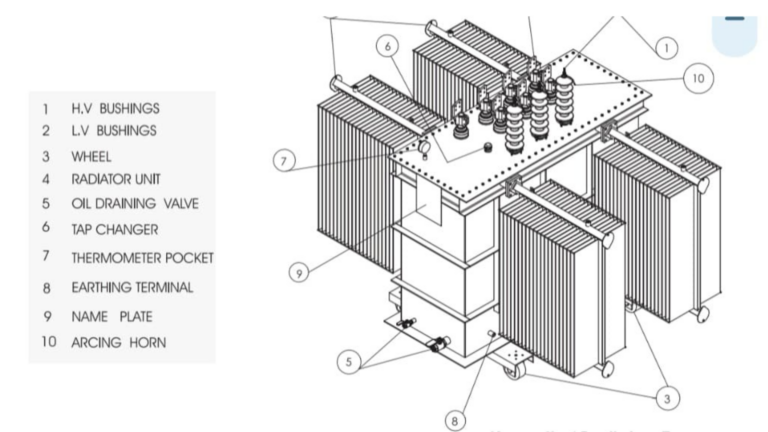

Construction

The core of a single phase transformer is made out of thin laminated sheets of silicon steel, usually 0.25–0.5 mm in thickness, with insulation between the laminations to reduce eddy current losses, thus increasing efficiency and heat reduction

The windings are commonly copper (occasionally aluminum), wound in concentric or pancake layers, and insulated with varnish, paper or resin. Smaller units may have dry insulation, while larger units are used in oil-filled tanks for assistance with cooling and insulation as needed. Core-type and shell-type constructions are most often used for a primary and secondary winding, respectively; each type has varying degrees of magnetic flux flow and leakage down to the ground.

Working Principle

The operation of transformers is based on mutual electromagnetic induction. When the primary winding is driven by alternating current, it develops a changing magnetic flux in the core, which induces voltage across the secondary winding. According to Faraday’s law, the induced EMF equals the turn ratio times the rate of change of flux:

Working Principle

This transformer operates on the principle of mutual electromagnetic induction. When alternating current is applied to the primary winding, it creates a changing magnetic flux in the core that cuts through the secondary winding, inducing a voltage across the winding. The induced electromotive force (emf), E_2, is equal to the turn ratio (n) times the rate of change of magnetic flux:E=4.44fNΦ

The relationship between primary and secondary voltages are proportional to their respective number of turns (Vp/Vs=Np/Ns ) while the currents are inversely related (Is/Ip=Np/NsI_s/I_p = N_p/N_sIs/Ip=Np/NsTransformers can therefore step down or step up voltage levels while keeping the AC frequency constant.

Key parameters and performance

Efficiency is an important measure of an electrical machine—single phase transformers normally have efficiencies of 95–99%, and when a single phase transformer operates efficiently, losses in copper (I²R) and iron (eddy current or hysteresis) will be equal. Voltage regulation measures the change in output voltage resulting from loading; a well-designed transformer will show little change in output voltage as it operates from no-load to full-load.

Voltage will not only be affected by loading, but also by impedance (which combines resistance from windings and loss associated with the core), and stress of either active or long-duration operations will introduce additional losses from winding resistance and core cores. Performance can be measured subjectively or objectively using standardized tests of open-circuit and short-circuit or by measuring inputs and outputs. Knowing the efficiency, regulation, and thermal performance will allow owners and operators to monitor and regulate normal performance. Impedance and leakage flux will be needed to assess potential for parallel operation with other transformers, and fault performance.

Types & Configurations

From a physical design standpoint the two types of transformer configurations are core-type (windings around separate core limbs) and shell-type (both windings surrounding a central core limb) and each offers different flux paths and leakage characteristics.

Functional types include distribution (step-up or step-down), isolation (1:1 ratio), welding (low voltage power), UPS, lighting, or traction transformers.

Winding types such as single-voltage, dual-voltage, tap-changing, auto-transformer, and other characteristics allow them to be modified to regulate different input voltages and loads to work for various applications. These varieties help to make single phase transformers a versatile type.

Pros & Cons

Advantages include: rugged, robust design; high reliability; excellent effectiveness; voltage flexibility; and galvanic isolation across circuits. They are economic for low to medium power, are with minimum maintenance, and have relatively low noise.

However, the disadvantages include: more bulk and weight versus three-phase transformers at high power; inefficiencies with unbalanced loads; and challenges operating in parallel. Applications with very large power or consistent three-phase loads may find alternative technologies more attractive.

Uses

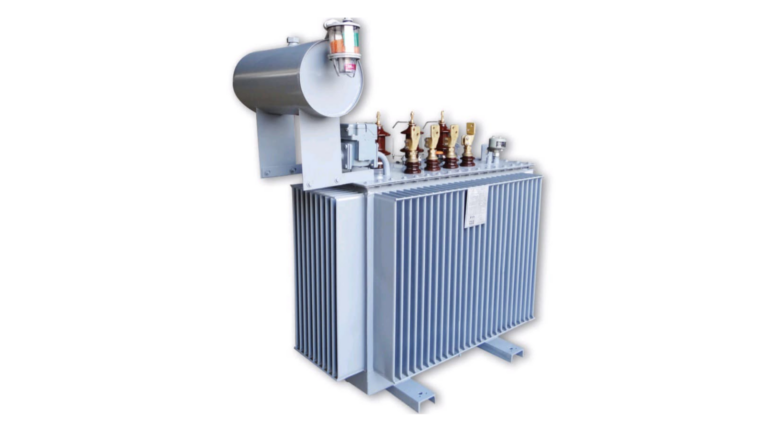

Single phase transformers are very widely used in residential power distribution which step down utility voltages to service level voltages ( 230 V/120 V). They are used in welding machines to supply very low voltages at high current, battery chargers, UPS systems, lighting circuits, electric traction the small industrial drive, and many other uses

.

Single phase transformer solutions for rural electrification and off-grid power systems are also very popular because of their simplicity and the low initial investment that makes them naturally suited for lower demand, single-phase networks.

Installation & Maintenance

Correct installation means that the electrical technician mounts the transformer with sufficient air circulation and safety onto a pole or pad. Cooling systems may also require air circulation or oil-cooling systems, such as radiators, and monitoring of temperature. Insulation should respect local standards for the management of moisture and to avoid contamination.

Maintenance:

Maintenance includes insulating oil analysis, inspection of windings and laminations for overheating, testing of electrical shields, testing of protection devices, and ensuring proper grounding and relay protection. If operating in parallel, ensure that impedance is equal, phasing is correct, and regulation tight. Continuation of regular maintenance will assist in the long and effective life of transformers.

Conclusion

Single phase transformers offer versatility, efficiency, and cost effectiveness with low to medium voltage. A single phase transformer’s design features, appropriate design practices (core lamination etc.), and robust design provide a reliable power source that offers protection from failure when used outside the failure current rating of the transformer. This functional equipment is designed to last for long periods. By recognizing and understanding key performance parameters, types of equipment, and where they are best suited, engineers and technicians can take advantage of the performance of the single phase transformer to safely provide efficient, inexpensive alternative AC power systems.