Three Phase Transformer | Complete Guide

Table of Contents

What is three-phase transformer?

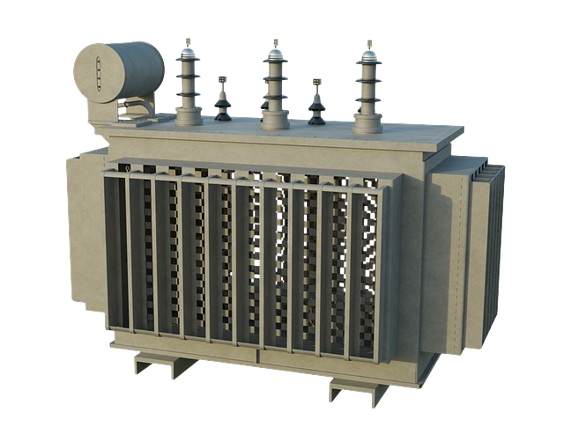

A three-phase transformer is a vital part of today’s electrical power system. It is used to transfer electric energy between two or more circuits through electromagnetic induction. A three-phase transformer has alternating currents having the same frequency and is out of phase (on 3-phase systems) by 120 degrees. A three-phase transformer can be built as a single transformer with the three phases built into a single core, or as a bank of three single-phase transformers.

Construction of Cores

Core type and shell type, or laminated structures are two main construction types. Core type construction has primary and secondary winding at each limb of the core, and the path of magnetic flux threads through all the limbs. Shell type is the opposite where the windings are encapsulated and surrounded by the core. In this construction type several limbs can be expensive. Shell type is compact and ideal for selected industrial applications. Making the selection of core type or shell type construction depends upon application requirements like voltage rating, insulation level and overall spatial controls.

Connection Configurations: Delta and Wye

Common connection configurations in transformer design include Delta (Δ) and Wye- (Y) also known as star, and combinations – Delta – Wye (Δ-Y) transformer. These configurations lead to designation of phase shift, neutral availability and load balance. For example, Delta to Wye (Δ-Y) configuration is a common transmission transformer. The advantages of using a transformer that is Delta to Wye transformer is that the Wye side provides a neutral point and the Delta isolates the primary from secondary. The transformative properties maximize a solidly grounded system, and reducing the risk of dangerous phase levels above 60 volts.

The Value of Three Phases?

Three-phase transformers are predominantly and widely utilized in commercial and industrial applications. This is because large power frequency electricity is transmitted via wide area networks efficiently to produce substantial economies and reductions in conductor materials. The three-phase transformer offers advantages such as reduced material consumption and continuous power transfer making motors and other electrical equipment run smoothly and also obviously, without interruption and potentially at less cost.

Benefits of Efficiency and Size

Three-phase transformers have many benefits associated with efficiency and size. For example: a single three-phase transformer operates at much higher efficiency, and occupies much less space, than three individual single-phase transformers. As a result of operating more efficiently, relative to weight and size, three-phase transformers generally cost less, particularly in high capacity applications where efficiency and material losses play a more significant role.

Cost Comparison with Single-Phase Units

In most cases of cost comparison, we know that it would be more cost-effective to have three-phase transformers than the equivalent set of single-phase transformers. A three-phase transformer is less expensive to install, there are fewer connections to make, and it is easier to maintain. Because of the shared core and tank, there is significant savings in both materials and labor.

Disadvantages of Three-Phase Transformers

However, there are a few disadvantages to three-phase transformers. If one phase fails, the result is zero power output. The operation of three phases is combined in a transformer, which can make maintenance, especially in regards to outages, very challenging and expensive. In other words, if single-phase transformers make up a transformer bank, there’s flexibility in when, where, and how you replace single-phase transformers; you may not have to take a whole system out of service.

Open-Delta Configuration

An open-delta configuration may be used when one of three transformers in a bank is out of service. The two remaining transformers are able to deliver power at approximately 87% of the original capacity. This feature is valuable for temporary or emergency situations.

Vector Groups and Phase Shift

Another thing to keep in mind with three-phase transformers is vector groups. Spectrum groups are used to classify the configuration and phase displacement of the primary and secondary windings. Choosing the correct vector group is important when paralleling transformers to avoid circulating currents as well as system compatibility.

Special Types: Scott-T and Zig-Zag Transformers

There also exist special types of three-phase transformers, Scott-T transformers that convert between three-phase and two-phase systems and zig-zag transformers for grounding, which creates a neutral point for ungrounded systems, and that also provides enhanced protection and voltage balancing in the event of a fault.

Operating Principle (Faraday’s Law)

The basic concept of three-phase transformers is founded on Faraday’s law of electromagnetic induction. The introduction of AC voltage to the primary winding creates a magnetic flux in the core, and that flux induces a voltage in the secondary winding. In a three-phase transformer, the three windings are spaced to create thirty-degree fluxes, or rotated 120 degrees apart, allowing the power to be supplied continuously and balanced.

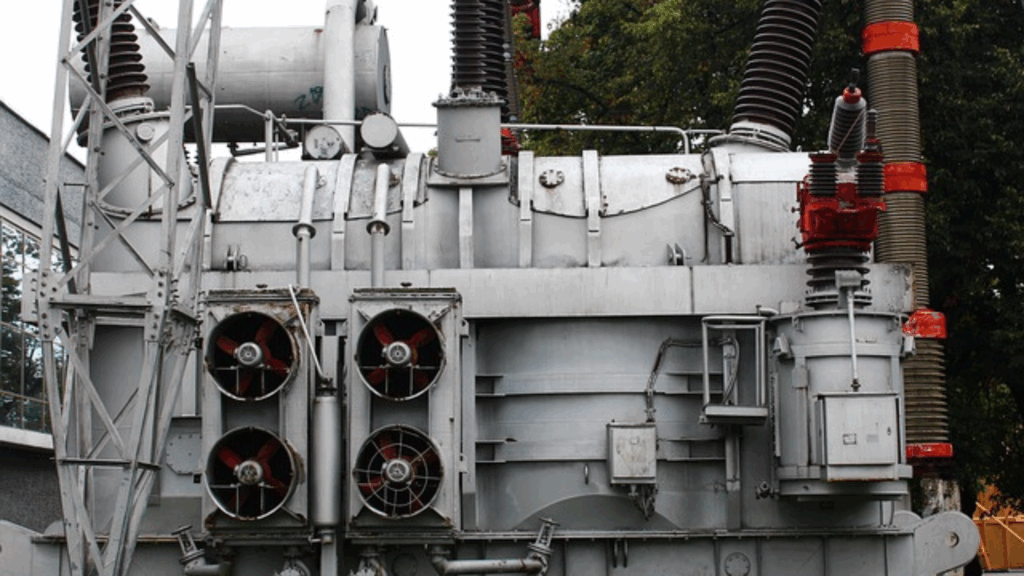

Cooling Systems and Insulation

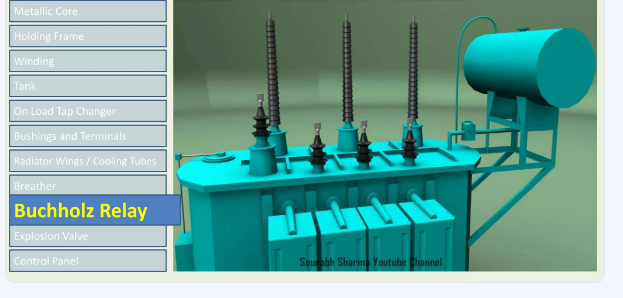

Proper cooling and insulation systems are important for the efficient operation and safety of a transformer. There are many types of cooling systems; the most common are natural air cooling, oil-immersed cooling, and forced-air or oil circulating. The insulation system protects the winding from electrical and thermal stress and uses materials such as paper, oil, and other synthetic materials.

Tips for Installation and Maintenance

The maintenance of three-phase transformers is much the same as other types of transformers, and the best practice includes regular inspections, logging and testing data. This includes checking insulation resistance, oil levels, examining the conditions of bushings and load tap changer operation. Preventive maintenance will help spot problems before they become failures and to avoid sudden, costly failures!

Utilization of Three-Phase Transformers

Three-phase transformers have many applications. You will find these supplying power to large industrial motors, transmission lines, commercial buildings, data centers, and manufacturing plants. Thanks to their compact and efficient design, which enables high power output, three-phase transformers are indispensable for electrical distribution systems.

Transformer Size Based on Load Requirements

In order to size a transformer, it is necessary to determine the load requirement. The formula for three-phase power is P = √3 × V × I, where V is line voltage and I is the line current. Engineers also account for growth in the future loads, temperature rise, and safety margins in order to determine acceptable performance.

Why Toroidal Three-Phase Units Are Non-existent

Toroidal three-phase transformers are simply non-existent because toroidal cores do not allow the harmonious three-phase flux paths. All conventional core structures, including the traditional three limb core, support the distribution of magnetic flux necessary for a balanced three phase systems.

Residential Three-Phase vs Single-Phase

Residential systems are primarily single-phase for household uses; however, electric utilities utilize three-phase transformers at the primary level, and then step down to single-phase at the consumer level. Every load in residential systems must be connected to a transformer that balances the load. Balancing loads on a three-phase system keeps the distribution network “clean,” and reduces costs associated with redundant infrastructure.

conclusion

To summarise, three-phase transformers have many advantages, with higher efficiency, lower costs and smaller designs, being three of the most significant. While there are negatives to a three-phase transformer, many of the positive attributes outweigh the negatives in most high-power applications. These transformers are critical to supporting reliable power delivery in industrial and utility sectors.